In the overall structural system of a ship, Ship Ladders are the core facilities that ensure the vertical passage of crew members, equipment maintenance, and emergency evacuation. Unlike conventional ladders in land buildings, Ship Ladders need to fully adapt to special working conditions such as swaying and tilting during ship navigation, while also addressing the challenges of high salt spray and high humidity corrosion in marine environments. They possess core characteristics such as high strength, high stability, and corrosion resistance. From the cockpit to the engine room, from the deck to the cargo hold, Ship Ladders are located in various key areas of the ship. Their design rationality and safety reliability directly affect the life safety of the crew and the operational efficiency of the ship, and are an indispensable and important component of the ship’s safety system.

The most prominent feature of a marine ladder is its steep inclination angle. Usually installed at an angle of 60 to 75 degrees to the horizontal plane, this nearly vertical design maximizes the saving of valuable ship space. In ships with dense compartments and numerous equipment, every inch of space is precisely calculated. Traditional staircase style stairs occupy too much flat area, while steep ladders cleverly utilize vertical space by only opening a narrow passage on the cabin wall. The pursuit of spatial efficiency stems from the essence of ship design – maximizing functionality within limited displacement.

However, steep angles pose challenges for use. To ensure safety, the design of the ship ladder is full of humanized considerations. Stairs are usually made of steel plates with surface punched or welded anti slip strips, which can provide reliable grip even in humid environments. The positions of the armrests on both sides have been ergonomically calculated to ensure that the arms are in a natural and effortless posture during climbing. Even more ingenious is the connection between the armrest and the steps, which uses continuous welding or special fastening to avoid any protruding parts that may hook clothes or cause danger. At critical locations, rest platforms will also be set up for users to make slight adjustments during long-distance vertical movements.

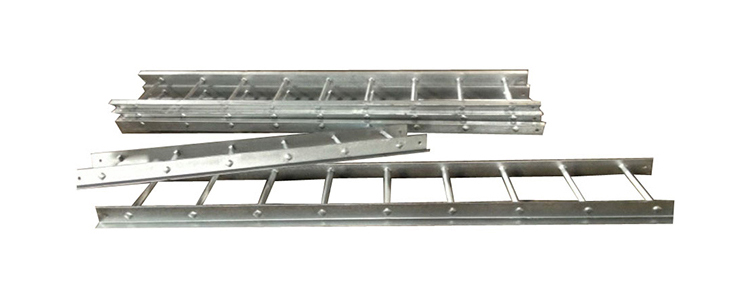

Material selection is key to ensuring the service life and safety performance of Ship Ladders, while meeting both strength and corrosion resistance requirements. At present, the mainstream Ship Ladders materials are mainly carbon steel, stainless steel, and aluminum alloy for ships. Among them, carbon steel materials have high strength and economy after anti-corrosion treatment such as rust removal, galvanizing, or painting, and are widely used in ordinary passage areas of ships; Stainless steel material is commonly used in high humidity and highly corrosive areas such as decks and engine rooms due to its excellent resistance to salt spray corrosion. It can effectively resist the erosion of seawater vapor and chemical media; Aluminum alloy material has the advantage of being lightweight. Although its strength is slightly lower than carbon steel, its weight is only about one-third of carbon steel, making it easy to install and transport. It is suitable for areas with strict weight restrictions such as ship superstructures. Some Ship Ladders in special areas will also use composite materials to further enhance their corrosion resistance and insulation performance.

Ship elevators are not only functional facilities, but also reflect the type and purpose of the ship. The ladder of the cargo ship is simple and sturdy, with practicality as the sole criterion; The ladder of the passenger ship may balance aesthetics by adding decorative elements to the handrails; The ladder of the warship takes into account the situation of battle damage and is designed with emergency alternative plans; The ladder of a research vessel may need to adapt to special environments such as polar low temperatures or tropical high temperatures. This differentiated design embodies the ship design philosophy of “form follows function”.

The application scenarios of Ship Ladders cover various key areas of ships, accurately matching different traffic and maintenance needs. In the cabin area, various inclined and vertical ladders crisscross, connecting different floors and equipment areas of the cabin, making it convenient for crew members to conduct daily inspections and maintenance of core equipment such as main engines and auxiliary engines; In the deck area, the inclined ladder connects the deck to the superstructure, and the ladder body needs to have wind and wave resistance capabilities, as well as anti slip devices to cope with the humid and waterlogged environment of the deck; In the cargo hold area, vertical and folding ladders are used in conjunction to provide access support for personnel supervision and equipment maintenance during cargo loading and unloading; In the driver’s cabin and crew living area, Ship Ladders balance convenience and comfort, and the staircase design is more ergonomic, enhancing the living and working experience of the crew.