Modern ships sailing on vast oceans are highly integrated and enclosed complex systems. The seemingly ordinary “covers” on its deck, including various hatch covers, manhole covers, and specialized closure devices, are actually the first key line of defense to ensure the safety of ship navigation, the integrity of cargo, and the structural integrity. These covering devices are not simply closed plates, but precision engineering systems that integrate structural mechanics, sealing technology, hydraulic or mechanical drive, and intelligent control. They must be able to withstand the impact of strong winds, huge waves, rainwater erosion, and huge dynamic loads for a long time in harsh sea conditions, ensuring absolute isolation of the internal space of the ship – whether it is the cargo hold, engine room, or various passages – from the harsh external marine environment. The reliability of the design, manufacturing, and operation of the huge cargo hold cover of a giant cargo ship to the tiny inspection hole cover of the engine room is directly related to the seaworthiness, cargo safety, and operational efficiency of the ship, and is an indispensable protective barrier in ship design and safety management.

The core value of Ship Covers is to build a flexible and reliable protective barrier for various cabin openings on ships, which can resist the invasion of external harsh environments during navigation, protect the cargo and equipment inside the cabin from damage, and flexibly open during loading and unloading, equipment maintenance and other operations, balancing practicality and convenience, providing comprehensive protection for the normal operation of ships.

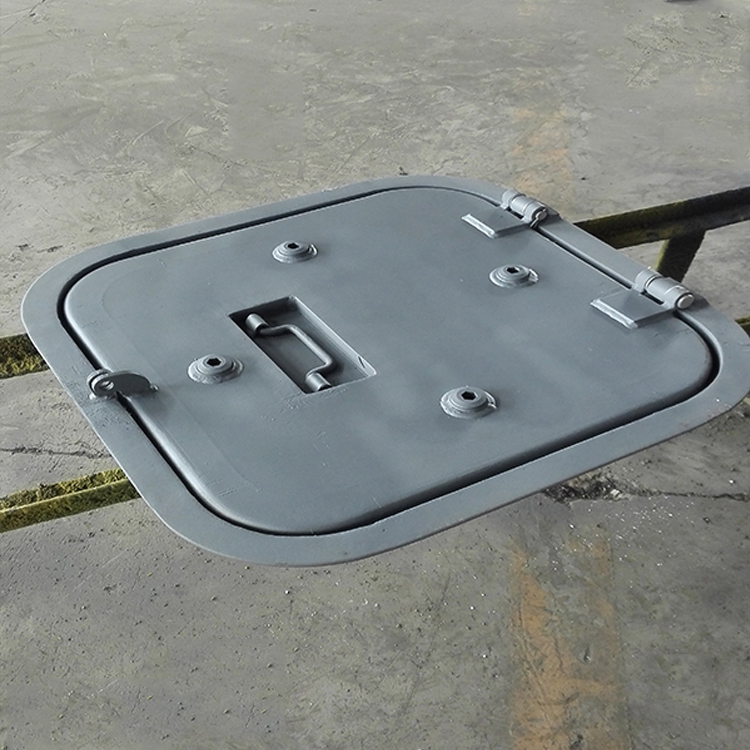

The implementation of its core functions closely conforms to the actual needs of ship navigation and operation: firstly, the core protection function. The opening of the ship’s cabin is the main channel for marine environment erosion of the cabin space. Splashing seawater, salt spray infiltration, rainwater infiltration, dust accumulation, and impact of marine debris may cause moisture, mold, rust, or damage to precision equipment, pipelines, and valves in the cabin, affecting the normal navigation of the ship. The ship covers can accurately cover various cabin openings, tightly block these external infringements, ensure that the cabin space is dry and clean, and provide a safe storage environment for goods and equipment; The second is the sealing and waterproof function, which is one of the most critical properties of the ship hatch cover. Through the scientific sealing structure design, it can effectively prevent seawater and rainwater from seeping into the cabin. Especially in bad weather (such as rainstorm, gale, huge waves) navigation, good sealing can avoid potential safety hazards such as the decline of ship stability and cargo damage caused by water ingress into the cabin; Furthermore, there is a convenient control function. The ship’s hatch cover needs to be suitable for unloading, maintenance and other operational requirements, and can be flexibly opened and closed. Some large ship hatch covers are also equipped with auxiliary control devices to improve operational efficiency and reduce crew labor intensity.

Throughout the entire operational cycle of a vessel, routine inspection, maintenance, and standardized operation of Ship Covers are the lifeline to ensure their continuous and effective working condition. Daily inspection includes visual inspection of the cover structure for deformation, corrosion, or cracks; Whether the sealing strip is aging, cracked or detached; Whether all locking devices, hinges, and rollers operate flexibly and without jamming; Is there any leakage in the hydraulic system and is the pressure normal. Before and after each opening and closing operation, it should be confirmed that there are no obstacles on the track and that the locking device is completely released or in place. The regular maintenance plan should include: cleaning the track and rollers, lubricating all moving parts, checking and adjusting the compression of the sealing strip, testing the performance of the hydraulic system and safety valve settings, and replacing vulnerable parts such as sealing strips if necessary. Before sailing in adverse weather conditions, additional confirmation must be made on the locking status of all hatch covers.

In summary, the various “covers” on ships are actually precise engineering barriers that safeguard ship safety, protect cargo, and protect personnel and equipment environments. They stand silently on the deck, enduring the most direct test of the ocean, and their technical content integrates structural mechanics, materials science, fluid dynamics, and automatic control. From resisting the raging waves of the North Atlantic to ensuring the cleanliness and dryness of precision instrument cabins, its value runs through every voyage.