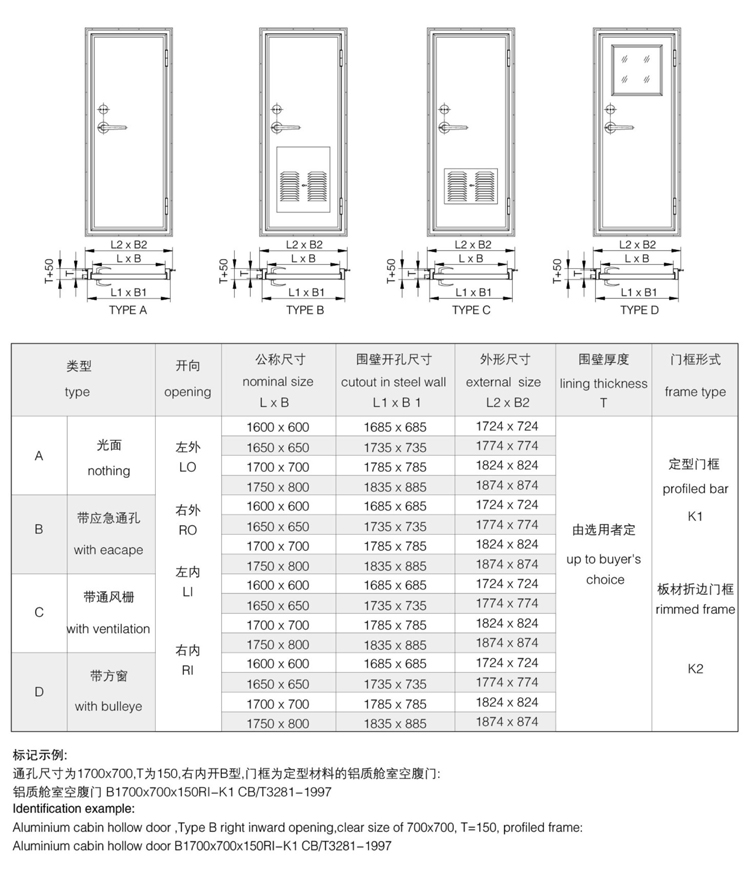

Description

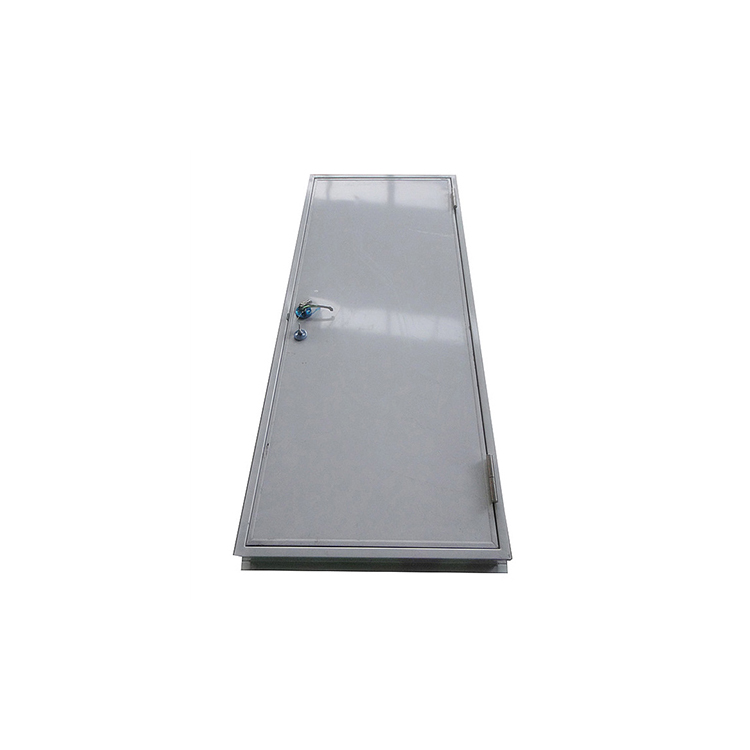

Made of aluminium alloy with new structure & good werthertight.

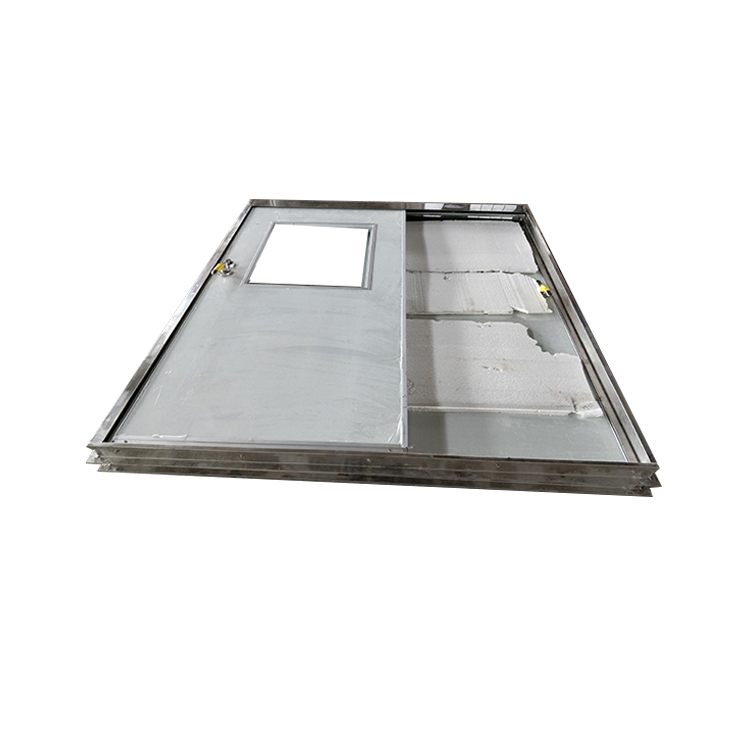

The aluminum cabin hollow door adopts high-strength aluminum alloy profiles and hollow structure design, which combines the characteristics of lightweight and high strength. It is specially developed for scenarios such as ships, rail transit, and mobile shelters that have strict requirements for weight and space. The product is manufactured through precision technology to meet special environmental requirements such as fire prevention, moisture resistance, and corrosion resistance, making it an ideal choice for modern cabin partitions.

Core advantages:

lightweight design

The hollow cavity structure reduces the weight of the door by more than 30%, reduces the load on the load-bearing structure of the cabin, and facilitates installation and handling.

Aluminum alloy material has low density and high strength, meeting the weight reduction standards for ships/vehicles.

High strength and stability

Using 6063-T5 or higher grade aluminum alloy, combined with internal reinforcement design, it has excellent impact resistance and can withstand cabin turbulence and vibration.

The door frame and door leaf are precisely interlocked, with good sealing and effective sound insulation (up to 30dB or more).

environmental adaptability

The surface is treated with anodizing or powder coating, resistant to salt spray corrosion (in accordance with GB/T 10125 standard), and suitable for humid marine environments.

Fireproof filling materials (such as rock wool) can be optionally selected to meet Class A fire protection requirements.

space optimization

Ultra thin door frame design (minimum 50mm), saving cabin space; Support bidirectional opening or push-pull customization, suitable for narrow passages.