On the vast and boundless ocean, ships are the mobile space for human activities and survival. The portholes, these transparent openings embedded in the hull structure, are far from simple components for lighting and viewing. They are the physical and visual interfaces that connect enclosed cabins with the vast ocean outside, undertaking multiple key missions such as ensuring safety, regulating the environment, and maintaining human physiological and psychological balance. The design, manufacturing, and certification of ship portholes embody the comprehensive requirements of ship engineering, materials science, human factors engineering, and regulatory systems, from robust watertight integrity to extreme mechanical load-bearing, and complex environmental adaptation. They are the crucial yet often underestimated technological core in ship design and construction, and can be called the “eye of the ocean” of ships.

The core value of Ship Windows lies in achieving the unity of the three core functions of “observation, protection, and adaptation” through scientific structural design and high-quality material selection, providing a safe and comfortable internal environment for ship navigation, while ensuring that crew members can grasp external navigation conditions in real time and respond to various sea risks in a timely manner.

The implementation of its core functions closely conforms to the actual needs of ship navigation: firstly, the observation function. As the “eyes” of the crew, the ship windows need to have a clear and unobstructed view to ensure that the crew can accurately observe the sea surface, route, navigation marks, other ships, and weather changes, providing reliable basis for navigation operations and collision avoidance decisions. Especially for the ship windows in the cockpit, there are extremely high requirements for the clarity of the view and observation range, which directly affects the accuracy of navigation operations; The second is the protection function. The ship will encounter complicated working conditions such as wind and waves, rainstorm, and seawater splash during navigation. The ship’s windows need to be able to effectively resist these external impacts, prevent seawater from seeping into the cabin, and at the same time resist seawater corrosion and ultraviolet aging, avoid window damage and deformation, and ensure the tightness and safety inside the cabin; Finally, there is the adaptation function. Ship windows need to adapt to the needs of different sea areas and navigation conditions, taking into account the performance of sound insulation, heat insulation, fire prevention, anti condensation, etc., to provide a comfortable working and living environment for crew members, while protecting electrical equipment and precision instruments in the cabin from external environmental influences, ensuring the normal operation of equipment.

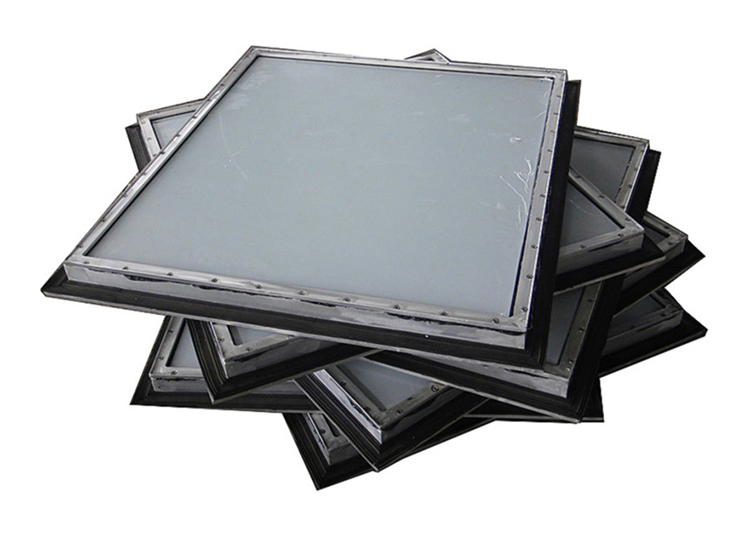

The excellent performance of portholes relies on rigorous material selection, precision manufacturing processes, and systematic testing and certification. Materials must undergo strict screening, and metal components must have excellent resistance to salt spray corrosion and be enhanced with appropriate surface treatments (such as anodizing and spraying) for protection. The manufacturing process of glass is strictly controlled to ensure its optical quality, absence of internal defects, and precise tempering treatment to obtain the predetermined surface compressive stress. The laminating process needs to ensure complete adhesion between layers, without bubbles or impurities. The assembly of the entire porthole needs to be carried out in a controlled environment, ensuring that the torque values of all fasteners and the compression of sealing strips meet the design specifications. The finished product must be sent to an authoritative testing institution for a series of destructive and non-destructive tests, which may include hydrostatic pressure testing, cyclic pressure fatigue testing, impact testing (such as hammer or soft heavy object impact), and environmental aging testing.

As the core guarantee of ship navigation safety, the performance of Ship Windows directly determines the safety of ship navigation, the comfort of crew, and the overall stability of ship operation. It occupies an irreplaceable and important position in the field of ship manufacturing and navigation. With the development of shipbuilding technology towards high-end, intelligent, and green directions, the performance requirements for ship windows will also be further enhanced. In the future, the industry will continue to promote technological innovation in ship windows. By optimizing structural design and developing new high-strength and corrosion-resistant materials, the impact resistance, sealing, and sound insulation performance of windows will be further improved. At the same time, intelligent technology will be integrated to achieve intelligent control and status monitoring of windows, thereby enhancing the intelligence level of ships. Whether it is merchant ships, fishing boats, yachts, or special vessels, Ship Windows will continue to play a core role in ensuring the safety of ship navigation, providing a comfortable and safe working and living environment for crew members, and becoming an indispensable core supporting component in the field of shipbuilding.