In the ship equipment system, Marine Windows is not a simple component for lighting and ventilation, but a core safety component that combines multiple functions such as protection, visual protection, sealing and insulation. The navigation environment of ships is complex and ever-changing, facing multiple tests such as wind and wave impact, seawater corrosion, alternating high and low temperatures, and ultraviolet radiation. Ship windows need to rely on special structural design, high-quality material selection, and strict process standards to resist the erosion of harsh marine environments, ensure the safety of personnel and equipment stability in the cabin, and provide clear views for navigation operations and observation. They are an indispensable and important component of various types of ships, widely used in various types of ships such as merchant ships, fishing boats, yachts, and special vessels.

The essence of marine portholes is a highly engineered special transparent opening device. Its core function is to introduce natural light and external views into the cabin while ensuring the integrity and water tightness of the hull structure, which is crucial for the physical and mental health and operational observation of crew members during long-term navigation. To achieve this goal, the design and construction of the portholes can be considered precise. A typical fixed or open porthole typically consists of thick window frames, high-strength transparent mirrors, multiple sealing systems, and sturdy fasteners and hinge mechanisms.

Window frames are often made of bronze, stainless steel, or special coated alloys that are resistant to seawater corrosion, and are firmly integrated with the ship’s structure through riveting or welding, becoming an integral part of the ship’s hull. Window mirrors are the focus of technology. In the early days, thick flat glass was used, while in modern times, high-performance transparent materials such as chemical or physical tempered glass, laminated safety glass, and even polycarbonate are commonly used. These materials not only need to have extremely high impact strength to resist the impact of splashes from waves, but also need to have good optical quality and anti-aging performance to keep clear under long-term ultraviolet radiation and temperature change. For ships sailing in polar regions, the portholes may even be equipped with electrically heated anti icing devices or special coatings to prevent icing or fogging and ensure unobstructed visibility.

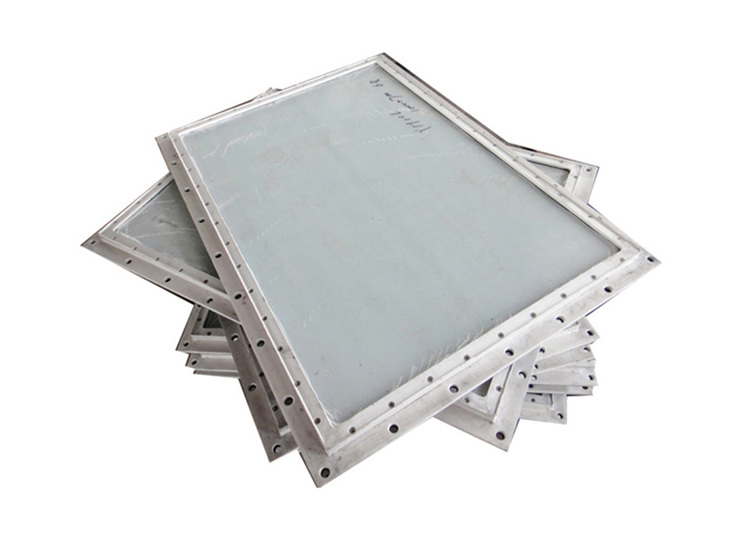

Material selection is the key to adapting Marine Windows to marine environments, and the materials of each component need to be targeted to meet the special challenges of marine environments. The window frame material is often made of corrosion-resistant aluminum alloy, stainless steel, fiberglass, etc. Among them, aluminum alloy material combines lightweight, high strength, and good corrosion resistance. After anodizing, spraying and other processes, it can further enhance the ability to resist seawater erosion and is the mainstream choice for small and medium-sized ships; Stainless steel material has high hardness and strong wear resistance, making it suitable for scenarios such as ocean going ships and special vessels that require higher strength and corrosion resistance; Glass fiber reinforced plastic has the advantages of light weight, good insulation and anti-aging, which can meet the needs of some special working conditions. Glass panels often use special types of glass such as tempered glass, laminated tempered glass, bulletproof glass, etc. Tempered glass has several times the impact strength of ordinary glass, and when broken, it forms obtuse small particles, which can prevent personal injury; After the laminated tempered glass is broken, the adhesive layer in the middle can bond the fragments, maintain overall integrity, continue to play a protective role, and adapt to key areas such as the cockpit and crew cabin.

The manufacturing of marine portholes is a process that combines material processing, precision manufacturing, and rigorous testing. From extrusion and processing of metal profiles to cutting, edging, tempering, and laminating of glass; From the customization and molding of rubber sealing strips to the precise assembly of all components; Each process must be carried out in a controlled environment to ensure dimensional accuracy and material properties. The assembled portholes must undergo a series of rigorous type tests, which simulate and even exceed actual sea conditions: hydrostatic tests verify their sealing and structural strength; Impact test to verify the shatter resistance of the window mirror; Fatigue testing evaluates its durability under long-term alternating loads; And salt spray test, high and low temperature cycle test, etc., to assess its corrosion resistance and weather resistance. Only by passing these rigorous tests of portholes can one obtain certification from the classification society and be allowed to install them on board.