On the vast and boundless ocean, whether it’s the ocean-going giant ships cleaving through the waves or the port vessels shuttling back and forth, there exist many seemingly ordinary yet crucial components on their intricate decks and cabins – marine covers. They may not be eye-catching, come in various shapes, some are heavy and solid, while others are lightweight and flexible, but together they form an invisible defense line for the safe and efficient operation of ships. These covers are far from being simple covers; they are precision equipment that integrates functionality, safety, and intelligence, silently guarding every voyage of the ship.

During the navigation and berthing of ships, various equipment is exposed to marine climate conditions for extended periods, facing multiple challenges such as salt spray erosion, wind and rain scouring, ultraviolet radiation, and debris impact. Marine Cover, as a crucial protective component of ship equipment, provides comprehensive protection for engines, instruments, deck equipment, and other components on board due to its excellent protective performance. It effectively extends the service life of equipment, ensures the safety of ship navigation and operational stability, and has become an indispensable and important part of the ship operation and maintenance system.

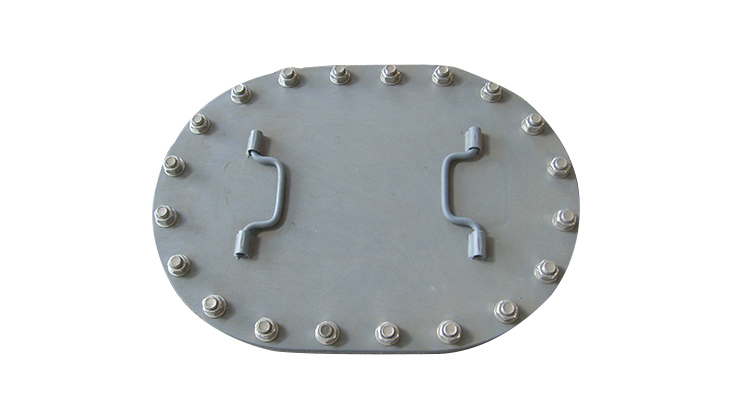

The primary duty of marine covers is to construct a reliable physical barrier to resist the harsh marine environment. The weather at sea is constantly changing, with sudden squalls, rainstorms, and waves up to several meters high, as well as pervasive corrosive salt spray, constantly testing every opening of the ship. Hatch covers must withstand immense watertight pressure to ensure that seawater cannot flood into the cargo or engine rooms; the louvers of ventilation ducts need to balance air circulation with preventing seawater from flowing backward; protective covers for various pipe orifices and valves must prevent foreign objects from blocking or salt accumulation from causing equipment corrosion and malfunction. Excellent marine covers undergo precise calculations and rigorous testing in terms of structural strength, sealing material selection, and the reliability of the locking mechanism, ensuring they remain sturdy under extreme sea conditions and provide a dry and safe environment for the ship’s interior space. This protection is the foundation for the ship to exist as an independent “floating city”.

Based on different protection objects and usage scenarios, Marine Cover has evolved into various types and specifications to accommodate diverse ship requirements. Divided by protection objects, there are Marine Covers dedicated to engines, protective covers for instruments and meters, protective covers for deck machinery, and covers for cabin openings; divided by usage functions, they can be classified into fixed protective covers and foldable and detachable protective covers. Fixed Marine Covers are suitable for equipment that is permanently installed, providing more durable and stable protection; foldable and detachable covers facilitate routine maintenance and repair of equipment, enhancing ease of use. For example, equipment such as anchor windlasses and winches on the ship’s deck are usually equipped with customized Marine Covers, which not only block the erosion of seawater and sea breeze but also prevent debris accumulation from affecting equipment operation; while some instruments and meters in the ship’s wheelhouse use transparent Marine Covers, which provide protection without hindering operators from observing data.

With the increasing demands for environmental protection and intelligence in the shipping industry, the connotation of marine covers is constantly expanding. In terms of environmental protection, preventing accidental leakage or dispersion of oil, chemicals, or cargo dust through openings has become an important design criterion for covers. Special sealing designs, collection tanks, or secondary sealing devices are integrated to comply with increasingly stringent international anti-pollution conventions. On the level of intelligence, covers are no longer just mechanical components. Smart hatch covers equipped with sensors and remote condition monitoring capabilities have emerged, which can sense the locking status, sealing pressure, and even structural stress in real time and transmit the data to the ship control center, enabling predictive maintenance and remote monitoring of safety status. This marks the evolution of marine covers from simple physical closures to intelligent nodes integrated with information sensing capabilities.

From a broader perspective, the design and manufacturing of marine covers is a comprehensive skill that integrates ship engineering, materials science, mechanical design, and marine environmental science. It requires consideration of the climatic characteristics of different sea areas, the type and service life of ships, as well as the mechanical environment of specific installation locations. From low-temperature-resistant polar navigation ships to oil tankers that shuttle through tropical seas all year round, there may be differences in the material formulations, anti-corrosion coatings, and operating mechanisms of the covers. Behind this lies profound industry experience, continuous research and development investment, and a deep understanding of the marine environment.